Composite Drainage Network

Product Description

Shanghai Yingfan Engineering Material Co., Ltd. is a composite drainage network and other earth work products supplier, located in Shanghai China. Man of our clients are large-scale enterprises, which are among Fortune Global 500 or listed companies, such as PetroChina, Sinopec, Yili group, Wanke group, Mengniu group, and so forth. And we have won a lot of small or huge biding related with geosynthetic usage programs in our country. Composite drainage netwok is our top sales product in our supply chain.

Composite Drainage Network Introduction

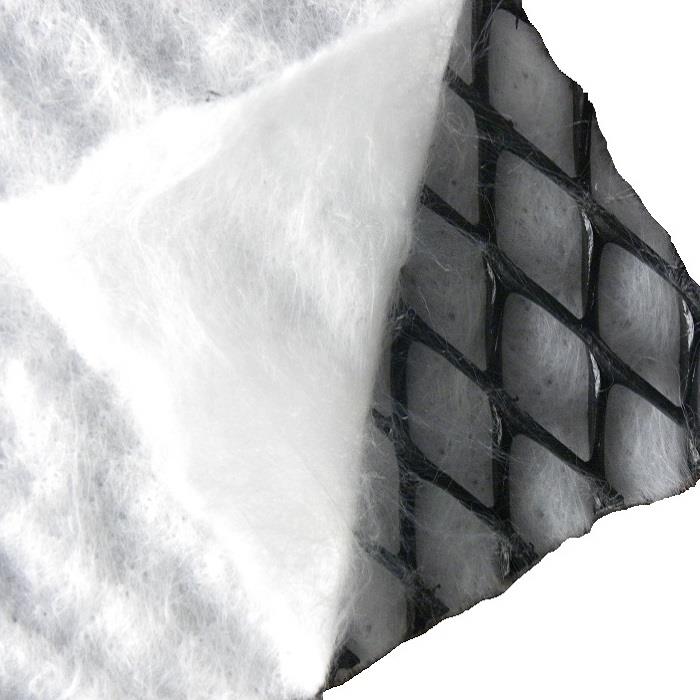

A Composite Drainage Network ( Geocomposite Drainage Liners ) is a new type of dewatering geotechnical material, which is designed to complement or replace sand, stone and gravel. It consists of a HDPE geonet heat-bonded with one side or both sides of nonwoven needle punched geotextile.

The geonet has two structures. One structure is bi-axial structure and the other is tri-axial structure.

Bi-axial structure / Tri-axial structure

Composite Drainage Network

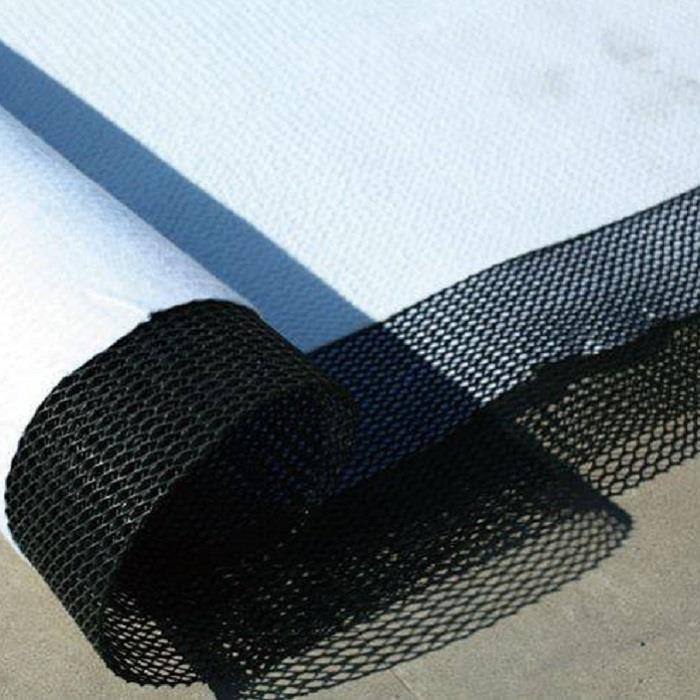

geotextile and drainage network

Its performance can meet or exceed our national standard GB/T17690.

Composite Drainage Network: how to work

| Composite Drainage Network | Network core | 1. Centralized middle HDPE strands provide channelized flow |

| 2. Upper and bottom fillet form support to avoid geotextile inserting into dewatering channel | ||

| Geotextile | one sided or double sided adhesive seepage geotextiles form a "filtration - drainage - ventilation - protection" overall performance |

Specification

| No. | Item | Unit | Spec./Standard value | ||||

| 1200g/m2 | 1400g/m2 | 1600g/m2 | 1800g/m2 | 2000g/m2 | |||

| 1 | Unit weight of compond production | g/m2 | ≥1200 | ≥1400 | ≥1600 | ≥1800 | ≥2000 |

| 2 | Thickness of compond production | mm | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 |

| 3 | Longitudinal tensile strength of compond productiong |

KN/m | ≥16.0 | ||||

| 4 | water diversion ration of compond production | m2/s | ≥1.2×10-4 | ||||

| 5 | peel strength of network core and geotextile | KN/m | ≥0.3 | ||||

| 6 | Thickness of network core | mm | ≥5.0 | ≥5.0 | ≥6.0 | ≥7.0 | ≥8.0 |

| 7 | Tensile strength of network core | KN/m | ≥13.0 | ≥15.0 | ≥15.0 | ≥15.0 | ≥15.0 |

| 8 | Unit weight of geotextile | g/m2 | ≥200 | ||||

| 9 | Seepage coefficient of geotextile | cm/s | ≥0.3 | ||||

| 10 | Width | m | 2.1 | ||||

| 11 | Length of one roll | m | 30 | ||||

Composite drainage network specifications:

1. Composite mass: 600g/m2---2000g/m2; geonet thickness range is 5mm~~10mm.

2. The width range is 2meter-6meters; Maximum width is 6meters; Other width can be custom.

3. The length can be 30, 50meters or as request. Maximum length is depending on the rolling limit.

4. Black color for geonet and white color for geotextile are most ordinary and popular.

Features and benefits

◆ High transmissivity (equal to 1meter thick gravel);

◆ High mechanic strength;

◆ Minimizing geotextile intrusion and maintaining stable transmissivity;

◆ Long-term life span of high or low load;

◆ Easy installation, cost and time effective (compare to traditional construction material such as sand, gravel and stone).

Application

◆ Erosion control;

◆ Foundation wall drainage;

◆ Landfill leachate collection in landfill liners, Leak detection, Caps and closures;

◆ Methane gas collection;

◆ Pond leak detection;

◆ Roadway and pavement drainage and other subsurface drainage system applications.

FAQ

Q1: Can I get a sample from your company?

A1: Yes. We can provide free available sample. For special request sample, cost can be negotiated.

Q2: What is your minimum order quantity of your product?

A2: 1000m2 is for available stock of composite drainage network. But for short stock of our ordinary products, MOQ is 5000m2.

Q3: Which is your port of delivery of goods?

A3: Usually it is Shanghai port because our company is located here. But if you want to delivery goods from other ports of China, we can help to arrange.

Drainage is a critical factor when designing a civil engineering project. Dozens of years ago, we usually use the natural drain aggregate such as sand, gravel to drainage liquid appearing in such project. As per the polymer synthetic material development, more and more synthetic products are created and used to directly replace or be combined with those traditional aggregate because of their features of good performance, low cost and easy installation.