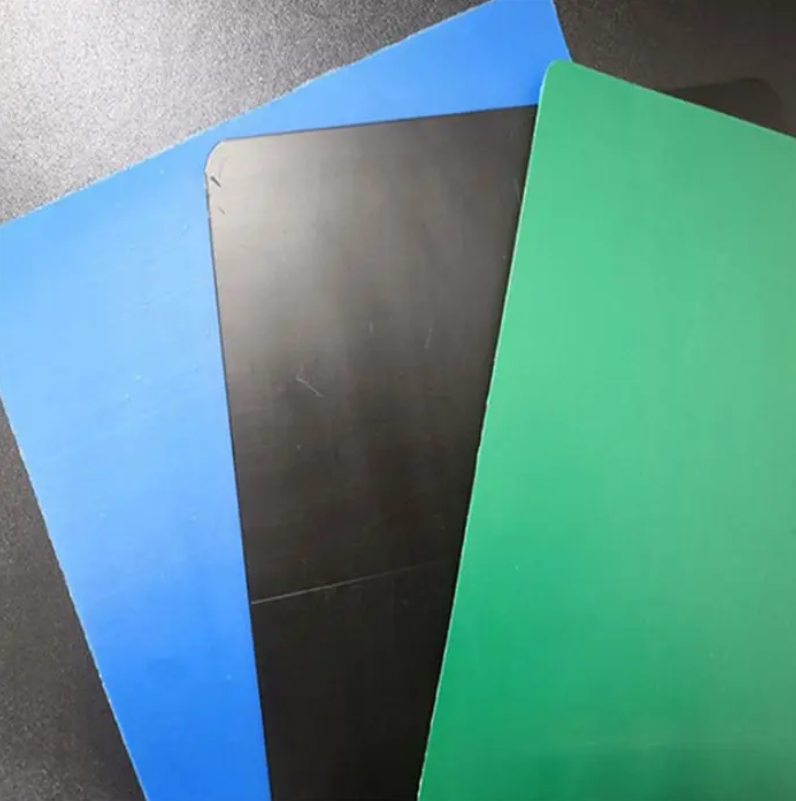

Geomembrane liners are essential materials used in various construction and environmental projects to prevent the seepage of liquids and gases. Among the different types of geomembrane liners available in the market, HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), and LLDPE (Linear Low-Density Polyethylene) geomembrane liners are widely used. Each type of geomembrane liner has its own unique properties and applications, making it important to understand the differences between them.

HDPE geomembrane liners are made from high-density polyethylene, a thermoplastic polymer known for its strong and durable properties. HDPE liners are commonly used in applications where high chemical resistance and UV resistance are required, such as in landfill liners, mining operations, and pond liners. The material’s high tensile strength and puncture resistance make it suitable for projects that require long-term durability and protection against environmental factors.

PVC geomembrane liners, on the other hand, are made from polyvinyl chloride, a synthetic plastic polymer known for its flexibility and resistance to chemicals. PVC liners are often used in applications where flexibility and weldability are important, such as in water containment, decorative ponds, and agricultural ponds. PVC geomembrane liners are known for their ease of installation and ability to conform to irregular surfaces, making them a popular choice for various containment projects.

LLDPE geomembrane liners are made from linear low-density polyethylene, a flexible and resilient material known for its puncture resistance and elongation properties. LLDPE liners are commonly used in applications where flexibility and elongation are crucial, such as in floating covers, secondary containment, and canal liners. The material’s ability to conform to the substrate and resist punctures makes it suitable for projects that require a high level of flexibility and durability.

When comparing HDPE, PVC, and LLDPE geomembrane liners, several key differences become apparent. HDPE liners are known for their high tensile strength and chemical resistance, making them suitable for applications where long-term durability is essential. PVC liners are valued for their flexibility and weldability, making them ideal for projects that require easy installation and conformity to irregular surfaces. LLDPE liners are prized for their flexibility and puncture resistance, making them suitable for applications that require a high level of resilience and elongation.

In conclusion, the choice between HDPE, PVC, and LLDPE geomembrane liners depends on the specific requirements of the project. Each type of geomembrane liner offers unique properties and advantages, making it important to consider factors such as chemical resistance, flexibility, and puncture resistance when selecting the most suitable material for a particular application. By understanding the differences between HDPE, PVC, and LLDPE geomembrane liners, engineers and project managers can make informed decisions to ensure the success and longevity of their containment and environmental protection projects.

Post time: Jul-25-2024