Geogrids have become an essential component in civil engineering and construction, particularly in applications involving soil reinforcement and stabilization. Among the various types of geogrids available, PP Uniaxial Geogrids and Uniaxial Plastic Geogrids are widely used due to their strength and durability. However, when selecting the right geogrid for a project, it is crucial to understand the differences between MD (Machine Direction) and XMD (Cross Machine Direction) properties, as these can significantly impact performance.

What are Geogrids?

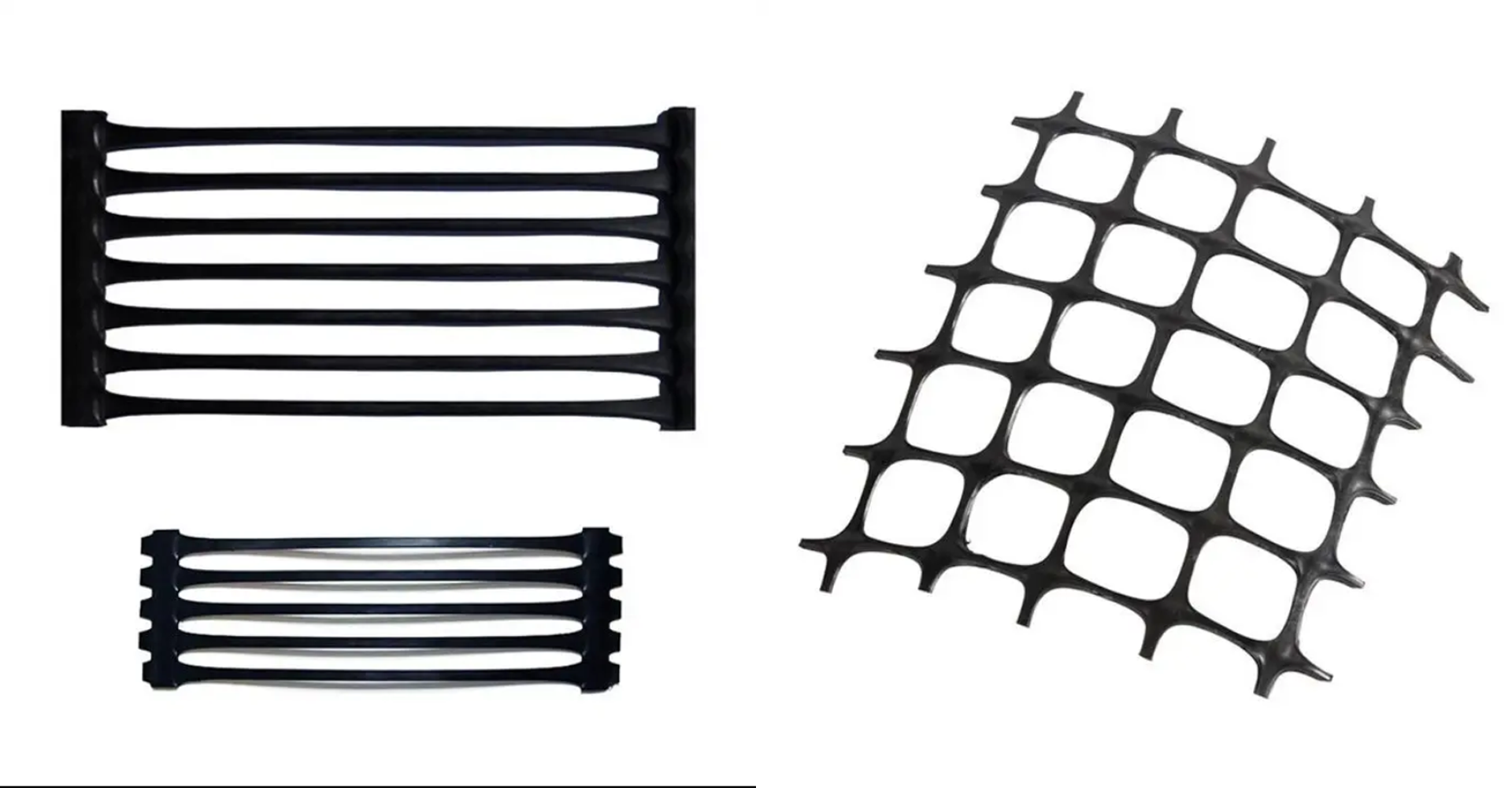

Geogrids are polymeric materials that are used to reinforce soil and other materials. They are typically made from high-density polyethylene (HDPE) or polypropylene (PP), which provides excellent tensile strength and durability. PP Uniaxial Geogrids, in particular, are designed to provide high strength in one direction, making them ideal for applications such as retaining walls, slope stabilization, and road construction.

The Importance of MD and XMD

When discussing geogrids, MD and XMD refer to the orientation of the geogrid’s strength.

MD (Machine Direction): This is the direction in which the geogrid is manufactured. The tensile strength in this direction is typically higher because the manufacturing process aligns the polymer chains to provide maximum strength. For PP Uniaxial Geogrids, the MD is crucial for applications where the load is primarily applied in this direction, such as in vertical walls or slopes.

XMD (Cross Machine Direction): This refers to the strength of the geogrid in the direction perpendicular to the machine direction. While the XMD strength is generally lower than the MD strength, it is still an important factor to consider, especially in applications where loads may be applied from multiple directions.

Key Differences Between MD and XMD

Tensile Strength: The most significant difference between MD and XMD is the tensile strength. MD typically exhibits higher tensile strength due to the alignment of the polymer chains during manufacturing. This makes it more suitable for applications where the primary load is applied in the machine direction.

Load Distribution: In many engineering applications, loads are not always applied in a single direction. Understanding the XMD properties is essential for ensuring that the geogrid can adequately distribute loads across different directions, which is particularly important in complex soil conditions.

Application Suitability: The choice between MD and XMD properties can influence the suitability of a geogrid for specific applications. For instance, if a project involves significant lateral loads, a geogrid with a balanced MD and XMD strength may be necessary to ensure stability and performance.

Design Considerations: Engineers must consider both MD and XMD properties when designing a project. The geogrid’s performance can be optimized by selecting a product that meets the specific load requirements in both directions.

Conclusion

In summary, understanding the differences between MD and XMD in geogrids, particularly in PP Uniaxial Geogrids and Uniaxial Plastic Geogrids, is crucial for successful project outcomes. The tensile strength in the machine direction is typically higher, making it suitable for specific applications, while the cross machine direction strength plays a vital role in load distribution and overall stability. By carefully considering these factors, engineers can select the appropriate geogrid to enhance the performance and longevity of their projects.

Post time: Oct-31-2024