In modern environmental and civil engineering, controlling fluid migration is critical for projects like landfills, reservoirs, and containment systems. One material that plays a pivotal role in these applications is the Geosynthetic Clay Liner (GCL). This article explores the permeability of Geosynthetic Clay Liners, explaining their structure, functionality, and why they are a preferred choice for hydraulic barriers.

Understanding Geosynthetic Clay Liners

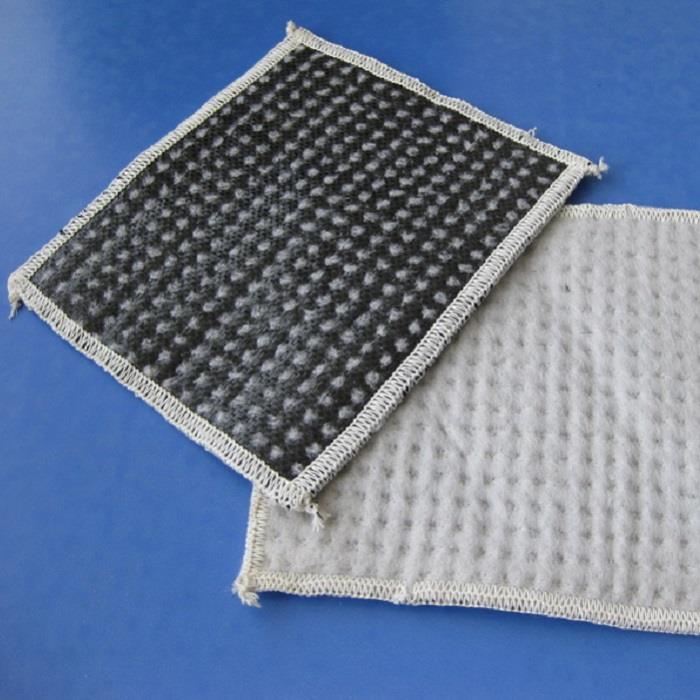

A Geosynthetic Clay Liner is a composite material combining geotextiles, bentonite clay, and sometimes geomembranes. The core component—sodium bentonite—is a highly absorbent clay that swells when hydrated, forming a low-permeability barrier. Sandwiched between layers of geotextiles, this clay layer ensures durability while maintaining flexibility.

The permeability of a Geosynthetic Clay Liner refers to its ability to restrict fluid flow. Measured in terms of hydraulic conductivity (typically ≤1×10⁻⁹ cm/s for GCLs), this property makes GCLs exceptionally effective in preventing contaminants or liquids from penetrating engineered structures.

Why Permeability Matters in Geosynthetic Clay Liners

Permeability is the defining characteristic of any hydraulic barrier. For Geosynthetic Clay Liners, low permeability ensures:

1.Environmental Protection: Prevents leachate from landfills from seeping into groundwater.

2.Structural Integrity: Reduces erosion in dams or canals by minimizing water seepage.

3.Regulatory Compliance: Meets strict standards for containment systems in industrial projects.

The swelling capacity of sodium bentonite is key here. When hydrated, the clay expands up to 15 times its dry volume, filling voids and creating an impermeable layer. Even under high hydraulic pressure, properly installed Geosynthetic Clay Liners maintain their barrier performance.

Factors Affecting the Permeability of Geosynthetic Clay Liners

While GCLs are reliable, their permeability can vary based on:

——Moisture Content: Dry bentonite has higher permeability; hydration activates its sealing properties.

——Compaction and Confinement: Adequate pressure during installation ensures uniform clay distribution.

——Chemical Compatibility: Exposure to aggressive chemicals (e.g., high-salinity fluids) may reduce swelling capacity.

Testing under site-specific conditions is essential to validate a Geosynthetic Clay Liner's performance.

Applications Leveraging Low Permeability of Geosynthetic Clay Liners

1.Landfill Caps and Bases: GCLs are widely used as secondary liners beneath geomembranes to contain hazardous waste.

2.Mining Operations: They prevent acid mine drainage from contaminating surrounding ecosystems.

3.Water Infrastructure: In canals or ponds, GCLs minimize seepage losses.

Compared to traditional compacted clay liners (CCLs), Geosynthetic Clay Liners offer faster installation, reduced thickness, and consistent permeability.

Maintenance and Longevity of Geosynthetic Clay Liners

Proper installation is critical. Punctures or inadequate overlap between GCL rolls can compromise permeability. Over time, bentonite self-seals minor damages, but regular inspections are recommended. When protected from UV exposure and mechanical stress, a Geosynthetic Clay Liner can last decades.

The Future of Geosynthetic Clay Liners

Advancements in material science are enhancing GCL permeability performance. Innovations like polymer-enhanced bentonite or hybrid liners (combining GCLs with geomembranes) are improving chemical resistance and adaptability to extreme environments.

Conclusion

Geosynthetic Clay Liners are a cornerstone of modern containment systems, offering unmatched permeability control. Their blend of geosynthetics and natural clay delivers cost-effective, eco-friendly solutions for fluid barriers. As industries prioritize sustainability, the demand for high-performance Geosynthetic Clay Liners will only grow.

By understanding their permeability mechanics and applications, engineers can deploy GCLs more effectively, ensuring safer and more durable infrastructure worldwide.

Post time: Feb-21-2025