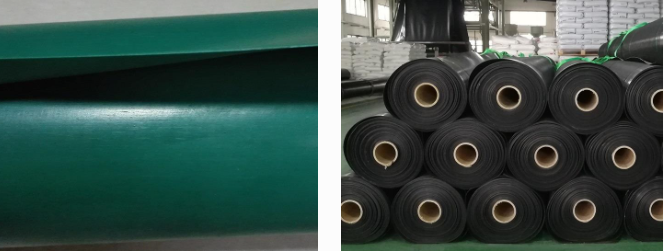

Both materials have their unique benefits and applications, but understanding their differences can help you make an informed decision. This article will explore the properties of HDPE linings, specifically those offered by HDPE lining suppliers, and compare them to PVC linings.

Learn about HDPE lining

HDPE liners are used in a wide variety of applications, including landfills, ponds, and agricultural projects. They are available in a variety of thicknesses, typically 0.15mm to 2.0mm, providing flexibility depending on the specific requirements of the project. The thickness of the lining can significantly affect its durability, puncture resistance, and overall performance.

Advantages of HDPE lining

1.Durability: HDPE liners are known for their superior strength and resistance to environmental stresses. They can withstand harsh weather conditions, UV radiation and chemical exposure, making them ideal for long-term applications.

2.Puncture Resistant: The strong properties of HDPE make it highly resistant to punctures and tears. This is especially important in applications where sharp objects may come into contact with the liner.

3.Environmental Impact: HDPE is a recyclable material, making it a more environmentally friendly choice compared to PVC. Many HDPE lining suppliers focus on sustainable practices to ensure their products have a minimal ecological footprint.

4.Cost Effectiveness: While the initial cost of HDPE lining may be higher than PVC, its longevity and durability often reduce the overall cost in the long run.

Learn about PVC lining

PVC lining is another popular choice for a variety of applications, including waterproofing and landscaping. They are generally more flexible than HDPE liners, which can be an advantage in some situations.

Advantages of PVC lining

1.Flexibility: PVC lining is more flexible than HDPE, making it easier to install in complex shapes and contours. This is especially useful on landscaping projects or when working with irregular surfaces.

2.Cost: PVC liners are generally less expensive than HDPE liners, making them an attractive choice for budget-conscious projects.

3.Chemical Resistance: PVC has good resistance to a wide range of chemicals, which can be beneficial in certain applications, such as chemical sealing.

Comparison of HDPE and PVC linings

When choosing between HDPE and PVC linings, the following factors should be considered:

1.Application: If your project requires a high level of durability and puncture resistance, HDPE lining from a reputable HDPE lining supplier may be a better choice. Conversely, if flexibility and ease of installation are more important, a PVC lining may be more suitable.

2.Environmental Considerations: If sustainability is a priority, HDPE lining is often a more environmentally friendly choice due to its recyclability.

3.Cost vs. Longevity: While the upfront cost of PVC lining may be lower, the long-term durability of HDPE can result in cost savings over time.

In conclusion

In summary, the choice between HDPE and PVC lining ultimately depends on the specific needs of your project. HDPE linings, especially those from trusted HDPE lining suppliers, offer superior durability and environmental benefits, while PVC linings offer flexibility and lower initial costs. By carefully evaluating your project requirements, you can make an informed decision that best suits your needs.

Post time: Sep-26-2024